From Analog to Digital: The Future of Denture Creation

The Evolution of Denture Creation: From Analog to Digital Techniques

Denture creation has come a long way since its inception. Traditionally, the process involved numerous manual steps, from taking impressions of the patient's mouth to crafting the dentures by hand. However, with the advent of digital technology, the field of denture creation has undergone a significant transformation. In the past, analogue techniques were the norm in denture creation. Dentists would use putty-like materials to take impressions of the patient's mouth, which were then sent to a dental laboratory for the fabrication of the dentures. This process was time-consuming and often resulted in inaccuracies due to human error.Embracing Technology: How Digital Denture Creation is Revolutionizing the Industry

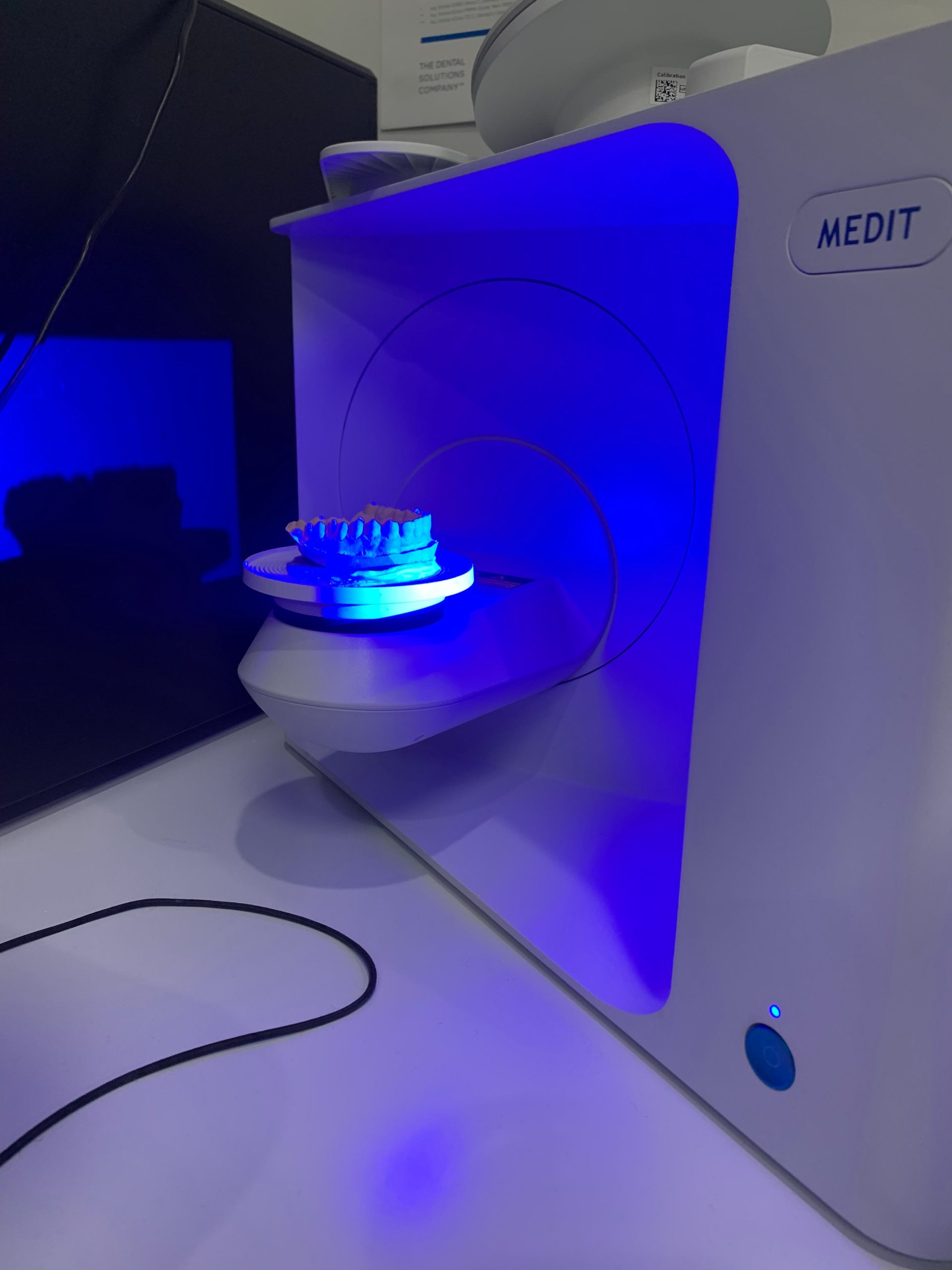

The introduction of digital denture creation has revolutionized the industry by streamlining the process and improving accuracy. Digital denture creation involves the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to create dentures with precision and efficiency. With digital denture creation, dentists can now take digital impressions of the patient's mouth using intraoral scanners. These scanners capture detailed 3D images of the oral cavity, eliminating the need for messy impression materials. The digital impressions are then sent directly to a dental laboratory, where the dentures are designed using specialized software.The Benefits of Digital Denture Creation: Accuracy, Efficiency, and Patient Satisfaction

One of the key benefits of digital denture creation is the increased accuracy it offers. Digital impressions provide a more precise representation of the patient's oral anatomy, resulting in better-fitting dentures. This improved accuracy leads to increased patient satisfaction and comfort. Digital denture creation also offers significant time savings compared to traditional analog techniques. The digital workflow allows for faster turnaround times, as there is no need to wait for physical impressions to be shipped to the laboratory. Additionally, the use of CAD/CAM technology enables the automation of certain manufacturing processes, further reducing production time. Furthermore, digital denture creation allows for greater customization and personalization. Dentists can easily modify the design of the dentures digitally, tailoring them to meet the specific needs and preferences of each patient. This level of customization enhances the overall aesthetic appeal of the dentures and improves patient satisfaction.Exploring the Process: Step-by-Step Guide to Digital Denture Creation

The process of digital denture creation involves several steps. First, the dentist uses an intraoral scanner to capture digital impressions of the patient's mouth. These impressions are then sent electronically to a dental laboratory, where a dental technician uses specialized software to design the dentures. Once the design is finalized, the digital files are sent to a milling machine or 3D printer, depending on the chosen manufacturing method. The milling machine or 3D printer then fabricates the dentures using high-quality materials. Finally, the dentures are finished and polished by the dental technician before being delivered to the dentist for placement in the patient's mouth.Overcoming Challenges: Adapting to the Digital Era in Denture Creation

While digital denture creation offers numerous advantages, it also presents challenges that need to be addressed. One of the main challenges is the initial investment required to adopt digital technology. Dentists and dental laboratories need to invest in intraoral scanners, specialized software, milling machines, or 3D printers, which can be costly. Another challenge is the learning curve associated with digital denture creation. Dentists and dental technicians need to undergo training to become proficient in using the new technology and software. However, with proper training and support, these challenges can be overcome, and the benefits of digital denture creation can be fully realized.The Future is Here: Predictions and Innovations in Digital Denture Creation

The future of denture creation lies in further advancements in digital technology. One exciting innovation is the use of artificial intelligence (AI) in denture design. AI algorithms can analyze large datasets of patient information to create highly personalized denture designs that optimize fit, function, and aesthetics. Additionally, the integration of 3D printing technology is expected to play a significant role in the future of denture creation. 3D printers can produce dentures directly from digital files, eliminating the need for milling machines and reducing production time even further. This technology also allows for the creation of complex geometries and customized textures, enhancing the natural appearance of the dentures. In conclusion, digital denture creation has revolutionized the industry by improving accuracy, efficiency, and patient satisfaction. The transition from analogue to digital techniques has streamlined the process and eliminated many of the limitations associated with traditional methods. While challenges exist, the future of denture creation looks promising, with innovations such as AI and 3D printing poised to further enhance the field. Dentists and dental laboratories that embrace digital technology are well-positioned to provide their patients with superior dentures that meet their unique needs and preferences.Tags

3D Dental Imaging

AI

braces

CAD/CAM

Cheap Denture

Dental Care

Dentristry

Denture

Denture Creation

denturist

Digital Data

Digital Dentistry

digital denture

Digital Denture Studio

DIY

Expansion

future

Growth

investing

investment

investor

invisible braces

new market

nhs

opportunity

Personlized Dentures

Press

Reducing Dental Visits

revolution

smiles